Trending...

- Men's Health Network Highlights Major 2025 Achievements & Launches New Donation Platform For Greater Impact

- Australian Aboriginal Cultural Immersions and First Nations Workshops

- T-TECH Partners with Japan USA Precision Tools for 2026 US Market Development of the New T-TECH 5-Axis QUICK MILL™

SHAOXING, China - PennZone -- TKL Group officially opened its new factory in Zhuji, China on 2025. The new facility provides expanded development space and more advanced facilities, further enhancing our service capabilities and innovation. TKL, already a major supplier to Meritor-Wabco, Haldex, and Fleetpride, currently produces 6 million units annually. Upon opening of the new facility, this capacity will reach 10 million units.

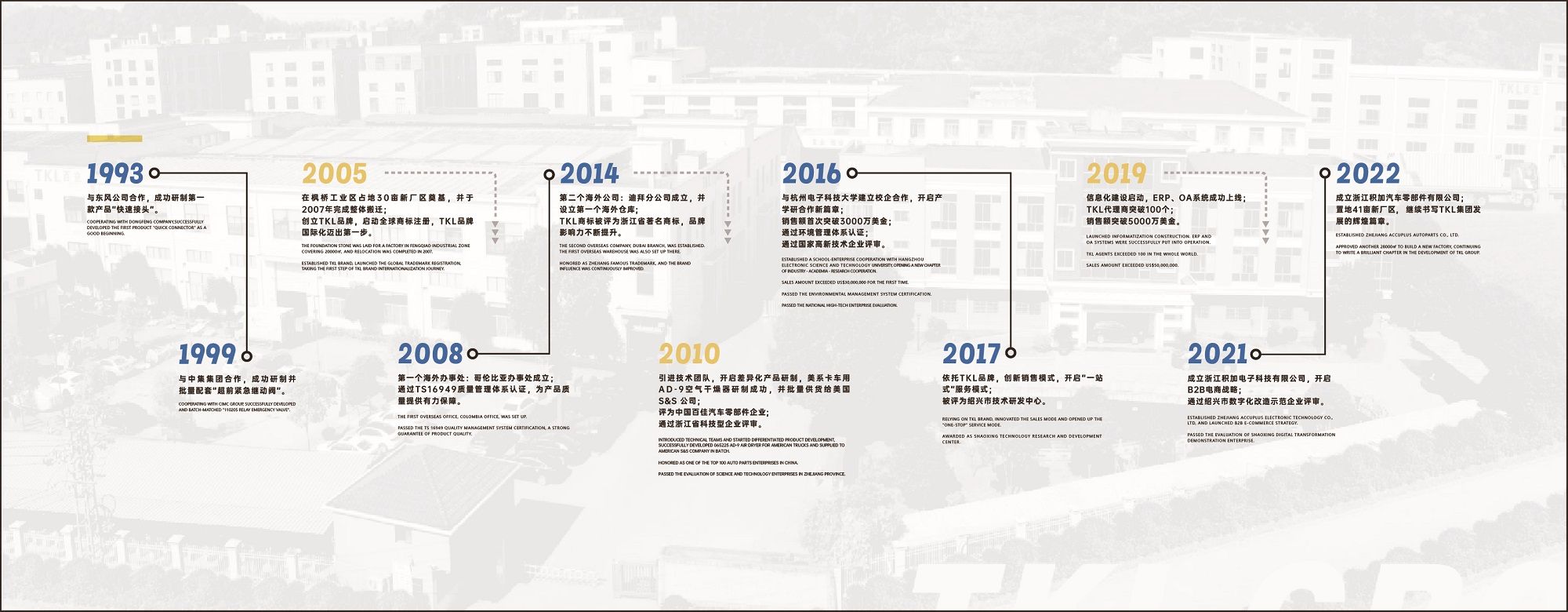

Looking back at our development history,from humble beginnings in a mountain village workshop to a global braking systems leader operating across 67 countries, TKL epitomizes the resilient ascent of "Made in China" through relentless innovation.Recognized as one of China's Top 100 Automotive Parts Suppliers and a National High-Tech Enterprise, we are redefining commercial vehicle safety standards worldwide, driving the "Made in China" initiative forward with groundbreaking technologies.

Over the past decade,our evolution from single chassis brake components to integrated system-level solutions has been fueled by deep expertise in the North American commercial vehicle market,specifically the heavy-duty truck segment.Guided by our "Deep Technology + Broad Service" strategy,TKL now emerges as the aftermarket's premier integrated supplier of full life-cycle support services.

Technological Innovation: Micron-Level Security Moat

In TKL's 43,000㎡ digital factory, 150 intelligent devices constitute a precision manufacturing matrix. Within a Class 10,000 dust-free workshop environment, vacuum leak sealing technology surpasses conventional industry limits, metal oxidation processes achieve significant enhancement in material performance, and 2μm-level three-coordinate detection ensures high-precision manufacturing. Millions of simulation operations are conducted to validate product reliability. The quality control standards implemented are substantially higher than industry benchmarks. The digital workshop, completed in 2022, enables real-time order tracking through 5G and industrial Internet integration, signifying TKL's transition from traditional manufacturing to digital and intelligent manufacturing.

More on The PennZone

Mode Upgrade: From Truck Parts Wholesale to System Solutions

By breaking through the limitations of single-product competition, TKL aggregated and integrated resources from 200 core suppliers, establishing a truck parts wholesale product matrix of over 10,000 types,and equipped with the integration capabilities across four key vehicle systems: braking,chassis, transmission, and body. Innovate the "product supermarket + technical manager" model to provide customers with customized solutions covering the entire vehicle's needs, and fulfill the value commitment of "saving time, effort, and cost".

Global Expansion: Operations in 67 Countries Highlight China's Manufacturing Strength

From dominating the heavy truck market in North America to supplying specialized vehicles for oil fields in the Middle East, and from supporting operations in the rain forests of South America to meeting stringent environmental standards in Europe, TKL's product matrix has continuously expanded across the globe, enhancing the international presence of the TKL brand in 67 countries. The establishment of three major technical service centers in the United States, Colombia, and the United Arab Emirates has successfully integrated "Chinese solutions" with localized service capabilities.

Service Innovation: Pain Points Drive the Innovation Ecosystem

Guided by the customer-centric philosophy of "ensuring safe and timely arrival",TKL has developed a comprehensive digital service system. This includes a real-time order tracking ERP system, intelligent warehousing enabling just-in-time (JIT) distribution, and a globally responsive technical team capable of on-site support within 72 hours. As the market enters a phase of full-scale competition, TKL has achieved value transformation through its "one-stop packaged service" model.

More on The PennZone

From a manufacturer of individual braking components to a fully integrated supplier, TKL has demonstrated over the past three decades that Chinese manufacturing enterprises are capable not only of breaking through technological barriers but also of reshaping the logic of industrial value distribution. Moving forward, we are committed to serving a broader customer base and fulfilling our mission of being customer-centric, delivering comprehensive automotive parts system solutions, and maximizing value creation for our clients.

Finally, we would like to thank all our customers and partners for their continued support and trust. We look forward to working with you all to create an even brighter future at a new starting point.

Contact:

www.tkltruckparts.com

export@tkltruckparts.com

Looking back at our development history,from humble beginnings in a mountain village workshop to a global braking systems leader operating across 67 countries, TKL epitomizes the resilient ascent of "Made in China" through relentless innovation.Recognized as one of China's Top 100 Automotive Parts Suppliers and a National High-Tech Enterprise, we are redefining commercial vehicle safety standards worldwide, driving the "Made in China" initiative forward with groundbreaking technologies.

Over the past decade,our evolution from single chassis brake components to integrated system-level solutions has been fueled by deep expertise in the North American commercial vehicle market,specifically the heavy-duty truck segment.Guided by our "Deep Technology + Broad Service" strategy,TKL now emerges as the aftermarket's premier integrated supplier of full life-cycle support services.

Technological Innovation: Micron-Level Security Moat

In TKL's 43,000㎡ digital factory, 150 intelligent devices constitute a precision manufacturing matrix. Within a Class 10,000 dust-free workshop environment, vacuum leak sealing technology surpasses conventional industry limits, metal oxidation processes achieve significant enhancement in material performance, and 2μm-level three-coordinate detection ensures high-precision manufacturing. Millions of simulation operations are conducted to validate product reliability. The quality control standards implemented are substantially higher than industry benchmarks. The digital workshop, completed in 2022, enables real-time order tracking through 5G and industrial Internet integration, signifying TKL's transition from traditional manufacturing to digital and intelligent manufacturing.

More on The PennZone

- 6 Holiday Looks That Scream "Old Money" But Cost Less Than Your Christmas Tree

- Tickeron Launches Next-Gen AI Corridor Bots: Consistent Exits for Stocks and ETFs

- From Cheer to Courtroom: The Hidden Legal Risks in Your Holiday Eggnog

- Controversial Vegan Turns Rapper Launches First Song, "Psychopathic Tendencies."

- Inside the Fight for Affordable Housing: Avery Headley Joins Terran Lamp for a Candid Bronx Leadership Conversation

Mode Upgrade: From Truck Parts Wholesale to System Solutions

By breaking through the limitations of single-product competition, TKL aggregated and integrated resources from 200 core suppliers, establishing a truck parts wholesale product matrix of over 10,000 types,and equipped with the integration capabilities across four key vehicle systems: braking,chassis, transmission, and body. Innovate the "product supermarket + technical manager" model to provide customers with customized solutions covering the entire vehicle's needs, and fulfill the value commitment of "saving time, effort, and cost".

Global Expansion: Operations in 67 Countries Highlight China's Manufacturing Strength

From dominating the heavy truck market in North America to supplying specialized vehicles for oil fields in the Middle East, and from supporting operations in the rain forests of South America to meeting stringent environmental standards in Europe, TKL's product matrix has continuously expanded across the globe, enhancing the international presence of the TKL brand in 67 countries. The establishment of three major technical service centers in the United States, Colombia, and the United Arab Emirates has successfully integrated "Chinese solutions" with localized service capabilities.

Service Innovation: Pain Points Drive the Innovation Ecosystem

Guided by the customer-centric philosophy of "ensuring safe and timely arrival",TKL has developed a comprehensive digital service system. This includes a real-time order tracking ERP system, intelligent warehousing enabling just-in-time (JIT) distribution, and a globally responsive technical team capable of on-site support within 72 hours. As the market enters a phase of full-scale competition, TKL has achieved value transformation through its "one-stop packaged service" model.

More on The PennZone

- Canterbury Hotel Group Announces the Opening of the TownePlace Suites by Marriott Portland Airport

- Heritage at South Brunswick's Resort-Style Amenities for Any Age and Every Lifestyle

- T-TECH Partners with Japan USA Precision Tools for 2026 US Market Development of the New T-TECH 5-Axis QUICK MILL™

- Hummell Brothers Celebrates 100 Years as Trusted Lighting Store in Jeannette

- Record Revenues, Debt-Free Momentum & Shareholder Dividend Ignite Investor Attention Ahead of 2026–2027 Growth Targets: IQSTEL (N A S D A Q: IQST)

From a manufacturer of individual braking components to a fully integrated supplier, TKL has demonstrated over the past three decades that Chinese manufacturing enterprises are capable not only of breaking through technological barriers but also of reshaping the logic of industrial value distribution. Moving forward, we are committed to serving a broader customer base and fulfilling our mission of being customer-centric, delivering comprehensive automotive parts system solutions, and maximizing value creation for our clients.

Finally, we would like to thank all our customers and partners for their continued support and trust. We look forward to working with you all to create an even brighter future at a new starting point.

Contact:

www.tkltruckparts.com

export@tkltruckparts.com

Source: TKL GROUP

0 Comments

Latest on The PennZone

- Explosive Growth in U.S. Cryptocurrency Cloud Mining Sets The Stage for New Platform Launch with Daily Rewards in a Transparent Revenue-Share Model

- Qtex Cierra Ronda de $7 Millones para Estandarizar la Banca Transfronteriza en los Mercados Emergentes de Latinoamérica

- Ring in the Season with Free Holiday Jazz from The Jazz Sanctuary

- America's Most Festive Garages Wanted for Garage.com's 2025 Holiday Contest

- FDA Accepts ANDA for KETAFREE™ as Analyst Sets $34 Price Target for NRx Pharmaceuticals: (N A S D A Q : NRXP) NRx is Poised for a massive Breakthrough

- BEC Technologies Expands MX-220 5G Industrial Router Series for Edge Connectivity

- "Latino Leaders Speak: Personal Stories of Struggle and Triumph, Volume II" Documents the Truth About Latino Excellence and Impact on American Society

- Broadway Smile Boutique Unveils Modern Website for Enhanced Patient Experience

- Fenix Consulting Group Expands Orange County Office to Meet Growing Client Demand

- Signature Smiles Dental Group Unveils New User-Friendly Website

- CCHR: New Data Shows Millions of U.S. Children Caught in Escalating Psychiatric Polypharmacy

- QwickContractReview.com Launches $19 Contract Review Service to Protect Consumers from Hidden Contract Risks

- Local Holistic Consultant Pharmacist Featured on National Podcast as FDA Updates Hormone Therapy Safety

- 100% Bonus Depreciation Places New Spotlight on Off The Hook Yacht Sales Inc. (N Y S E: OTH) as a Major Player in the $57 Billion U.S. Marine Market

- CNCPW Benchmarks Global Industry Standards: Integrating SEC Compliance with 3 Million TPS Architecture for Institutional Infrastructure

- The Patina Collective & Artist Jesse Draxler Debut "The Machine of Loving Grace"

- Smile! Dental Center Named 2025 "Best Dentist" in North Pittsburgh, Celebrating High-Tech Care and Heartfelt Service

- Dr. Johnny Shanks, As Seen on TV, Announces 20% Off Dental Implant Treatments | Tennessee's Leading All-on-X Provider

- Star Sleep & Wellness Expands to Pearland, Texas — Bringing Life-Changing Sleep Care to More Communities

- Fort Lauderdale Dentist Dr. Taskonak & IN A DAY SMILE Receive Emmy Nomination for Life-Changing Documentary "The Weight of a Smile"